Add to Cart

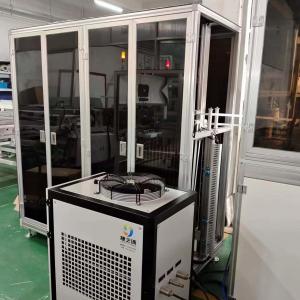

Tubular Film Welding Equipment, With Non-Stop Refuelling, Saving Film Raw Materials, Fast And Efficient Production!

Tubular membrane is one of the membrane forms that can best represent cross-flow filtration or cross-flow filtration. Tubular films are internal pressure, that is, the channel of the material liquid is a certain diameter of the tube. In addition to the tubular film of the organic film, the ceramic film of the inorganic film and the metal film all belong to the same mode. The tubular ultrafiltration membrane is an organic membrane. The ultrafiltration membrane produced by casting process is cut to make a tubular membrane core. A group of tubular membrane core and the outer membrane tube constitute the membrane component. The membrane manufacturing of tubular ultrafiltration membrane is the same as that of rolled membrane and flat membrane, but the molding process is different. Organic tubular ultrafiltration membrane has the characteristics of accurate organic membrane cutting molecular weight, and has a complete range of different cutting molecular weight membrane models to choose from. The flow diameter of tubular film is generally 6, 8, 10, 12, 14mm; The flow channel width of the plate film is 1.5~2mm, and the diaphragm is fixed with only two ends of the laminate. The gap of the rolled membrane flow channel is 31, 49millor, about 0.8, 1.2mm, and the middle is supported by the spacer net. Our equipment can be manufactured in all sizes.

As a pretreatment process, the effluent turbidity is less than 0.5NTU and SDI15 is less than 3.

1. Scope of application: suitable for welding of membrane tubes with diameters of φ5, 6, 8, 10, and 12.7mm;

2. Applicable non-woven fabric width: 17.5, 18.7, 20.5 and 24.5mm;

3. The width range of the non-woven fabric welding joint is 0.5-3mm, and the total thickness of the non-woven fabric is 0.1-0.5mm;

4. The speed of domestic non-woven fabrics can reach 3.2-3.6m/min, and the speed of imported non-woven fabrics can reach 5.2-6m/min;

5. It is suitable for feeding different kinds of trays;

6. It has the alarm function of material shortage, which can meet the non-stop refueling and improve production efficiency;

7. One-time completion of coiled pipe, welded pipe and inner scraping film;

8. Equipped with cloth tension control device to meet the constant tension during welding and ensure stable welding;

9. Equipped with a fabric thickness detection sensor to prevent wrong refueling and improve welding stability.

Configuration instructions:

| Pneumatic components | Airtac cylinder |

| Electronic control PLC | Omron |

| Operation interface | 10.5 flat touch screen |

| detection sensor | Japan Otex |

| servo motor | Yaskawa Electric |

| line track | Bank of Taiwan |

| bearing | NSK |

Company Profile Jiezhicheng Automation specializes in R&D, production, sales, ultrasonic, plastic welding machines, non-standard automation, hot-melt machines, testing equipment, automated assembly, fixtures, molds and other machinery and equipment. The company's main service industries: automotive, medical, Environmental protection, cosmetics, electronics, etc., core technical capabilities include, automatic welding equipment, post-processing of hollow board coaming box, post-processing equipment of automobile coaming, design and manufacture of non-standard automation equipment for medical device products, professionally provide medical device product welding Equipment has made significant contributions in the industry.There are many patents in ultrafiltration, MBR flat membrane, DTRO membrane and other water treatment equipment.The company has all kinds of processing equipment, can respond quickly according to customer needs, and guarantee customers' pre-sales and after-sales services.

1. Where is your factory located?

We are located in Suzhou City in South China, near to Shanghai City.

2. Are you a trading company or a manufacturer?

We are a manufacturer with more than 10 years experience solutions.

3. Why choose us?

A. We have 10+ experienced suppliers to help you know the best price and recommend the latest trends.

B. Our equipment is more durable and reliable. It will replace human labor hours.

C. We can provide ODM&OEM service according to your parameters and technical requirements. .

D. Our team understands your needs and provides excellent customer service and support.

4. What is the minimum order quantity?

Our MOQ is one set, and the price will vary according to the quantity.

5. What's the delivery time?

Generally, 45-60 days after confirming the order.

6. What is the payment terms?

We can accept T/T, Western Union, PayPal, MoneyGram.

Usually 50% deposit in advance, and pay the balance before shipping.

7. How about the quality assurance?

We will track every procedure and check the goods before delivery. Also will show you product and package pictures according to your request.

8. How to solve the fault problem?

If you are urgent, our team will provide you with online technical support in time.

If any parts are damaged, we can send new ones according to the specific situation. In conclusion, if you have any questions, please contact us, we will reply as soon as possible.

9. How to get the shipping cost?

Please advise your destination port or address so that we can check the shipment by sea or by air according to your request.